Product Overview

Our modular systems, with a small footprint optimizing floorspace, allow for numerous custom configurations, including adaptable load/off-load stations and optional modules for laser deflashing, marking, and product cleaning.

Alongside fully automatic solutions, we provide manual hand-fed systems suited for initial production phases, aligning with your scaling requirements.

POWER X1

Specifically designed for larger power packages (IGBT & IPM), Sempro’s fully automatic trim, form and singulation solution. It is purpose-built with press modules capable of long strokes and high forces while maintaining high trim and forming accuracy.

High Volume Dual Track

Developed for high output and a small footprint, proccessing both smaller leadframe packages and high-volume power packages, the HVDT machine can be equipped with a single or dual track. This versatility allows it to scale with customer demand or be utilized immediately for high production output.

Laser deflash & Product Cleaning

Sempro offers its Laser deflash and product cleaning solutions as integration modules or standalone systems, available in manual or automatic configurations and compatible with your preferred brands.

Cooper EM 5000

The Cooper EM5000 seamlessly executes Trim & Form processes for sensor packages, incorporating 100% Automated Optical Inspection, while autonomously sorting and rejecting defective units for a streamlined, precise workflow.

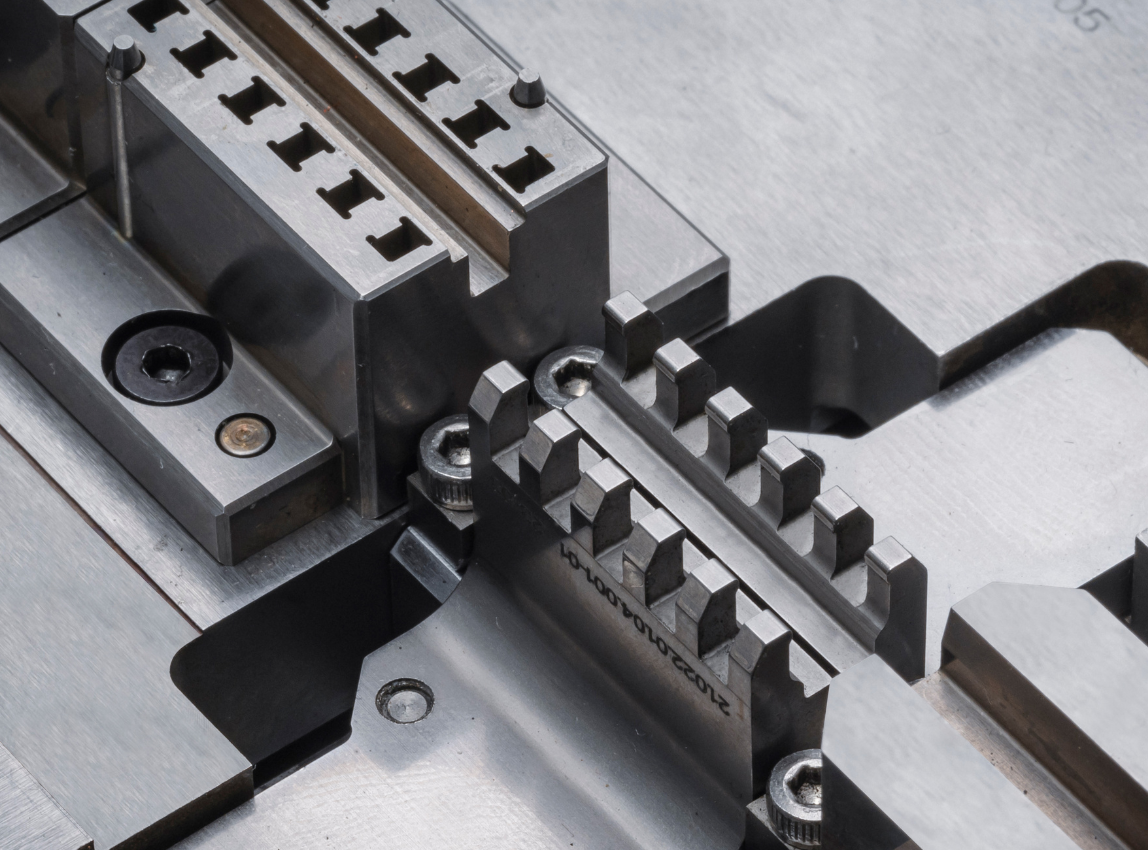

Tooling & Manual presses

With decades of experience in tool development, Sempro offers tooling and presses for all situations, ranging from small lots and development tools to fully automated equipment with machine-ready tooling.